Award-Winning Infinity Falls Canopy Project Keeps Guests Cool and Dry

- Entech Innovative

- Mar 30, 2020

- 2 min read

Updated: Jul 20, 2021

At SeaWorld Orlando’s Infinity Falls, guests climb aboard a raft and prepare to get soaked while floating through a South American rain forest in the middle of central Florida. When the breathtaking jungle cruise ends at Harmony Village, guests are invited to visit two canopy-covered kiosks that deliver information about freshwater ecosystems and water conservation.

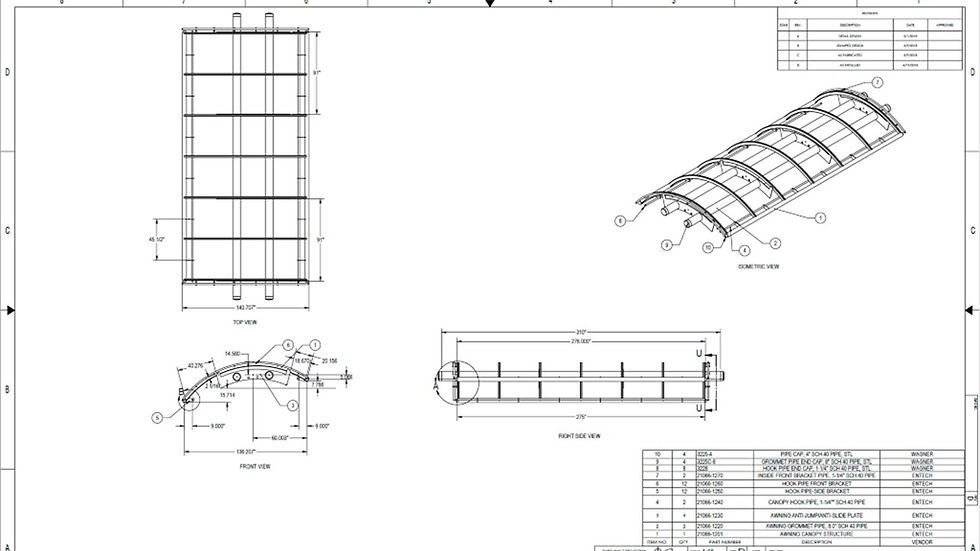

Entech Innovative Engineering provided the loading for the foundation design and the structure is chemically anchored to the already-built concrete slab. The central Florida based company also provided engineering, technical design, fabrication and installation for the two orange colored canopies with steel columns and a UV-resistant cloth roof that provides relief from the Florida sun and a place to dry off before the next adventure.

The technical design and engineering challenge behind these awnings came from sticking with the overall art direction for the new environment. These awnings had to resemble awnings that could be built in the middle of the Amazon while adhering to the codes laid out by the Orange County Building Department. This primarily includes the wind loading when it comes to central Florida.

Entech Innovative followed the allowable stress design (ASD) loading and calculation process. This resulted in following the guidelines of a based wind speed of 105 mph. The designed resultant wind unit force comes to 37 PSF in ASD. Utilizing these numbers, the calculations yielded loads of +/- 2kips in the X and Y directions and -3kips in the Z direction. The calculated moments came to +/- 14kip-ft in the Y direction and then +/- 19kip-ft in the X.

With all of that information, Entech Innovative was able to safely design this awning utilizing varying pipe sizes, as well as I-Beams, to get this awning structurally sound. Intricacies to this assembly that you may notice when visiting these pieces are the “mouse holes” at the bottom. These were needed to avoid water from pooling up in the area where the I-Beams were coming together which would’ve been a major problem for corrosion if water would have stayed in that area.

These holes were also designed to adhere to the ASTM Standards on hand entrapments. Another process of note is the way the roof attaches to the I-Beam subassembly by just fitting into the holed-out grooves on the plates. This allowed for the awning to be clocked per the direction of SeaWorld Orlando’s superb art direction team, but also made for a seamless install operation.

Once complete, Entech Innovative provided engineering design drawings and operation and maintenance instructions. The canopy project won a 2019 Central Florida Chapter of Associated Builders and Contractors Eagle Award.

Comments